TOMO | End-to-End Development

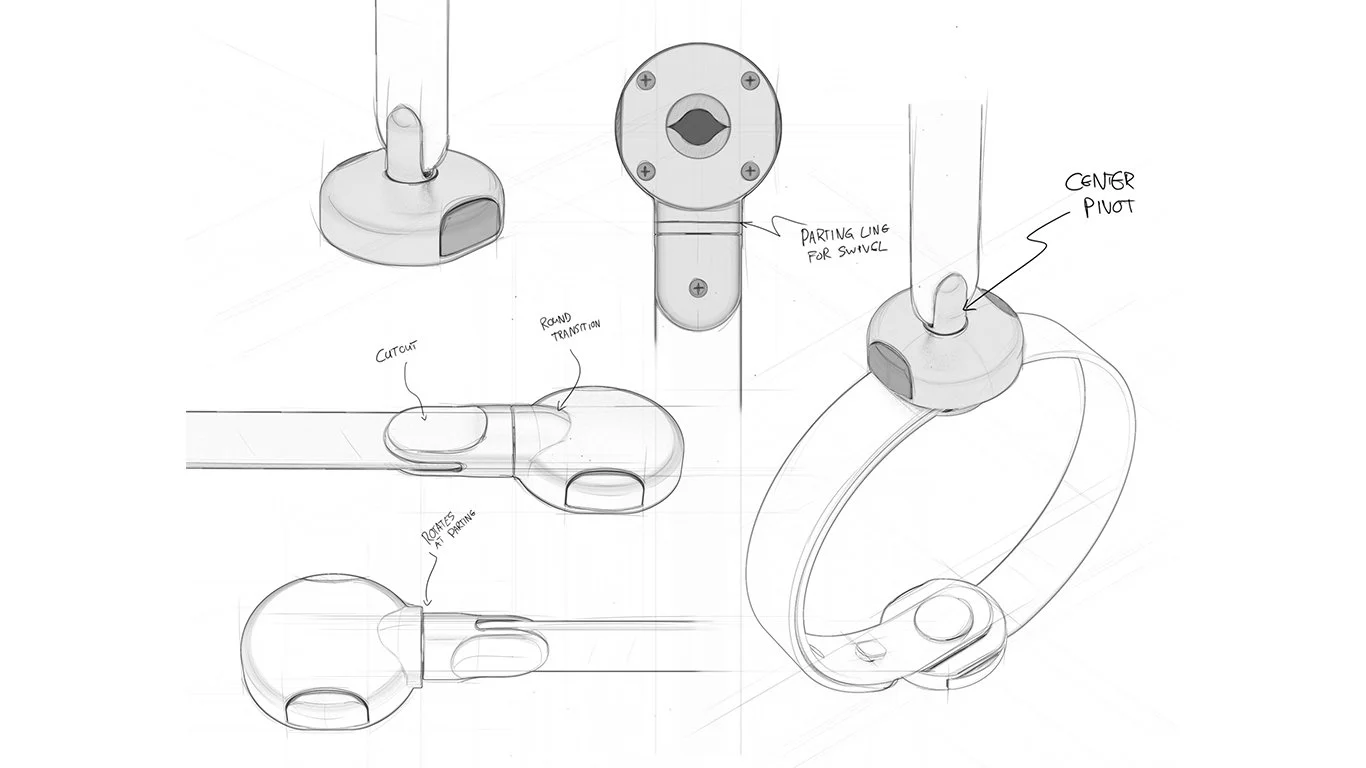

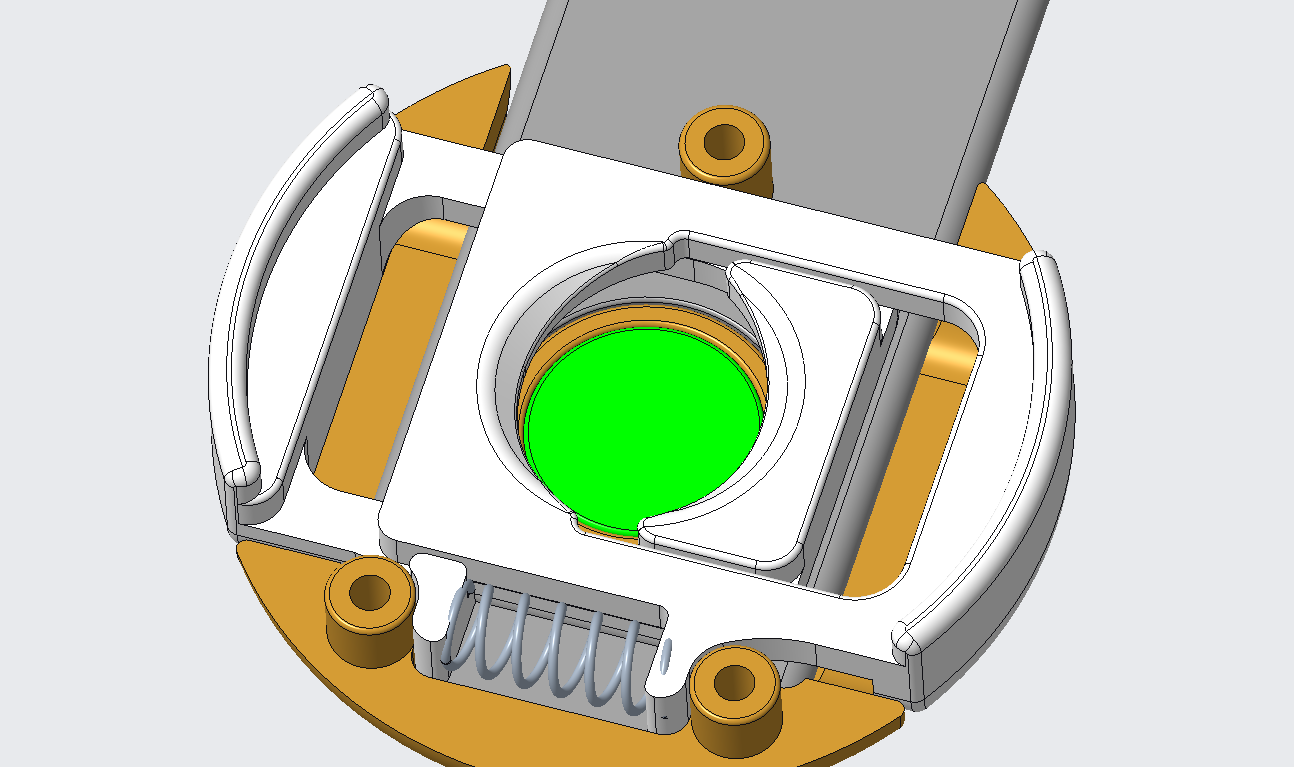

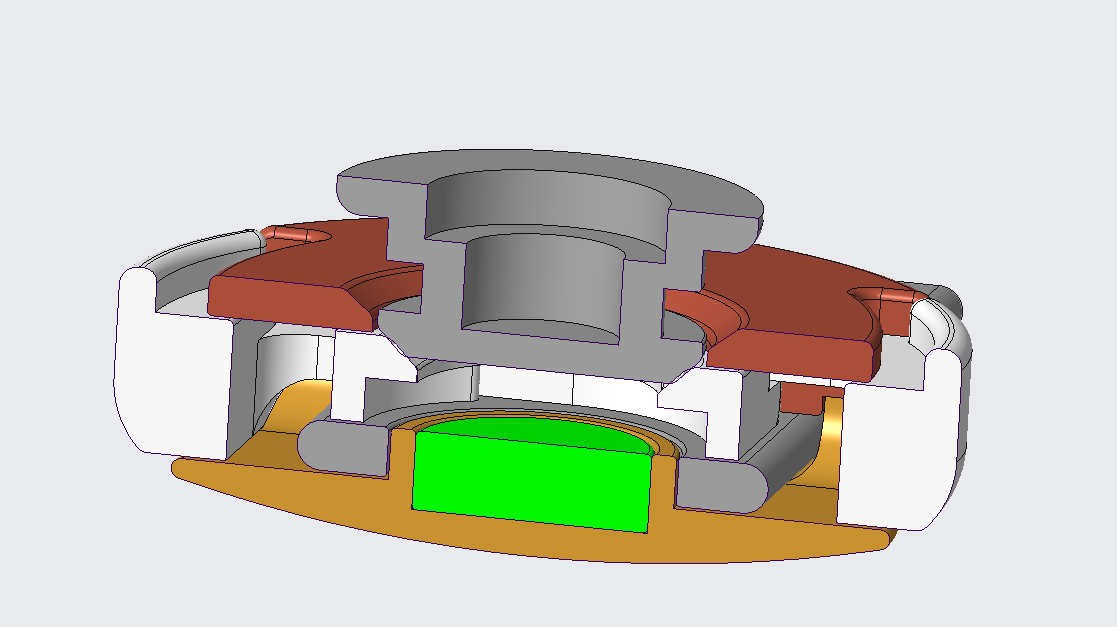

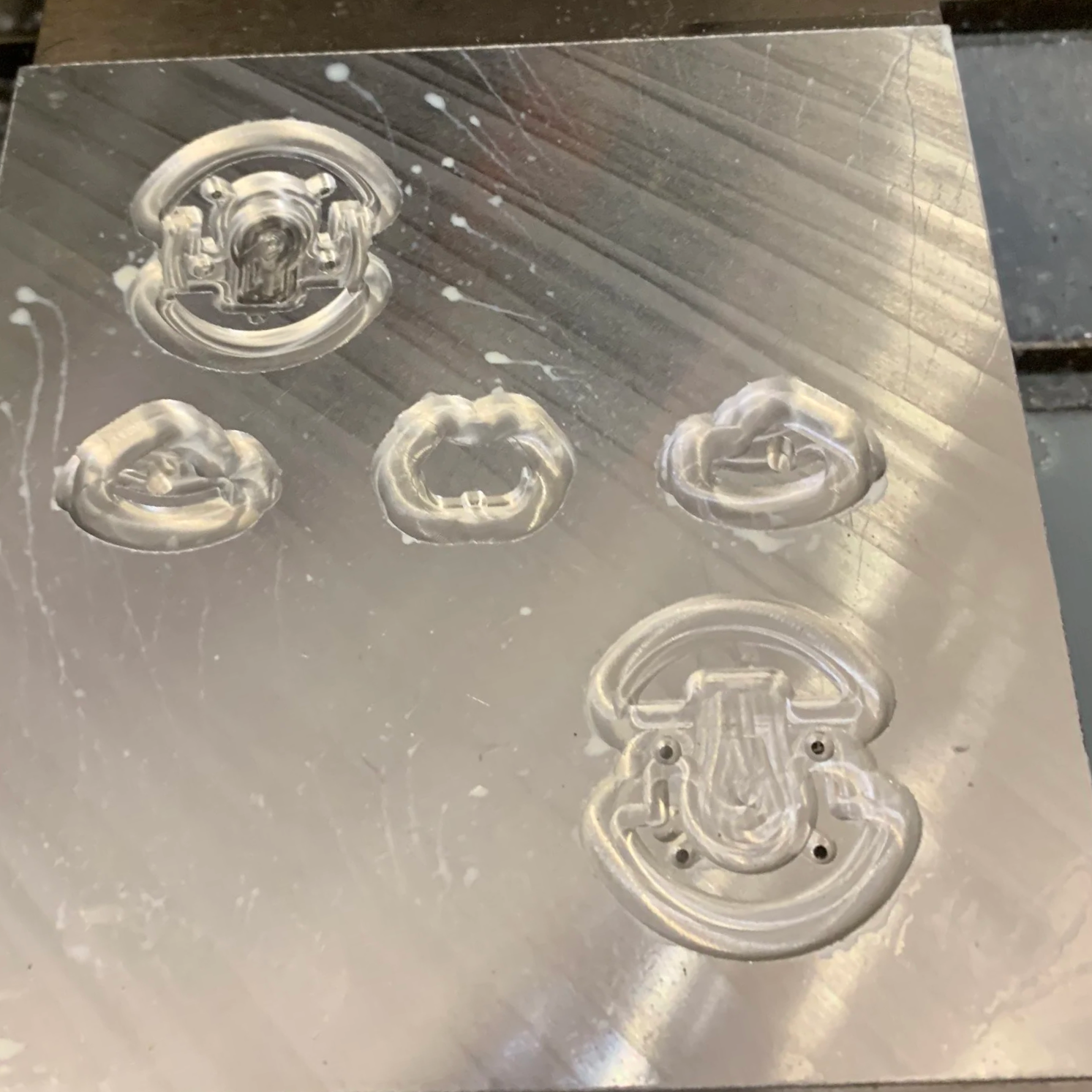

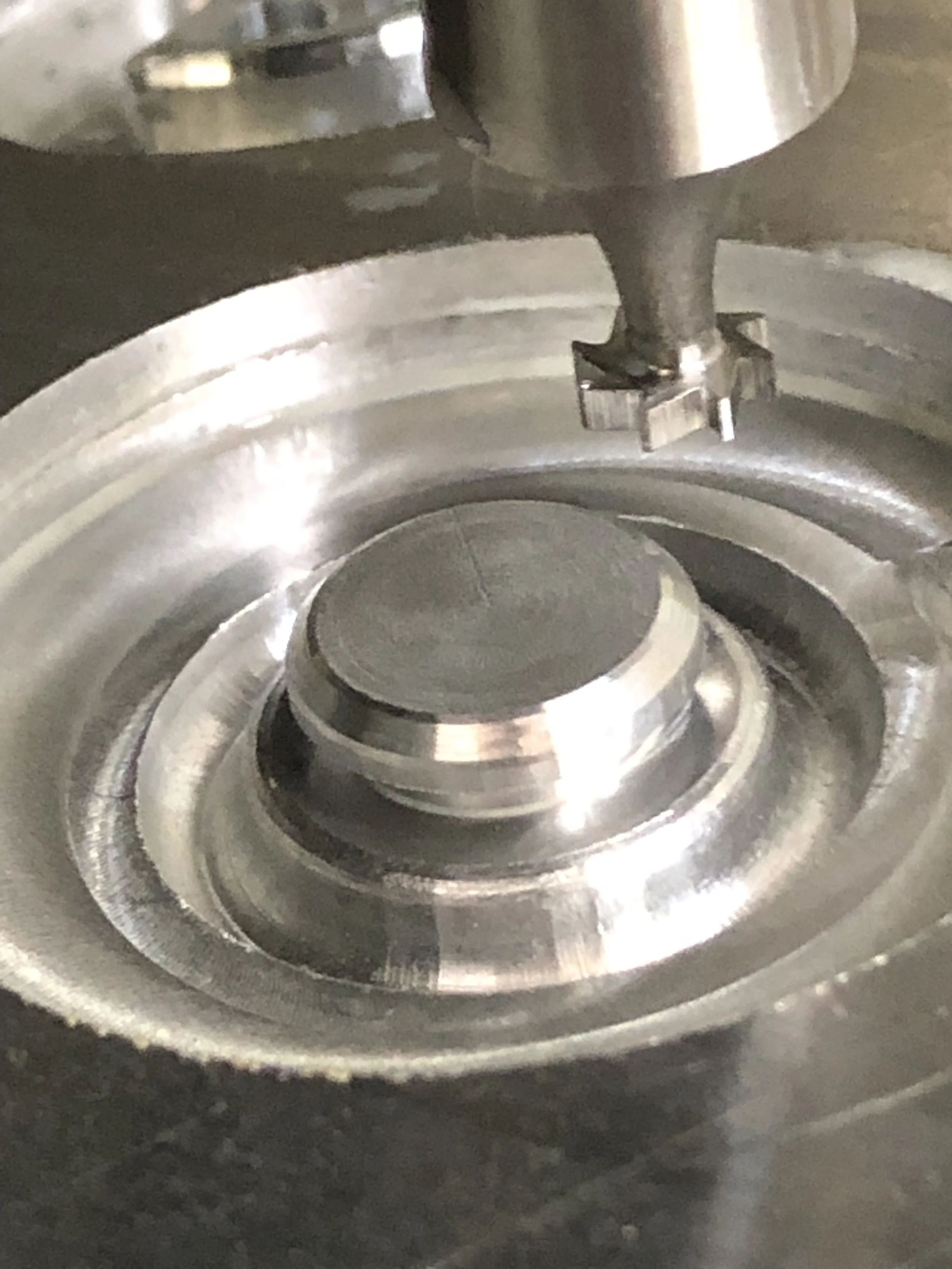

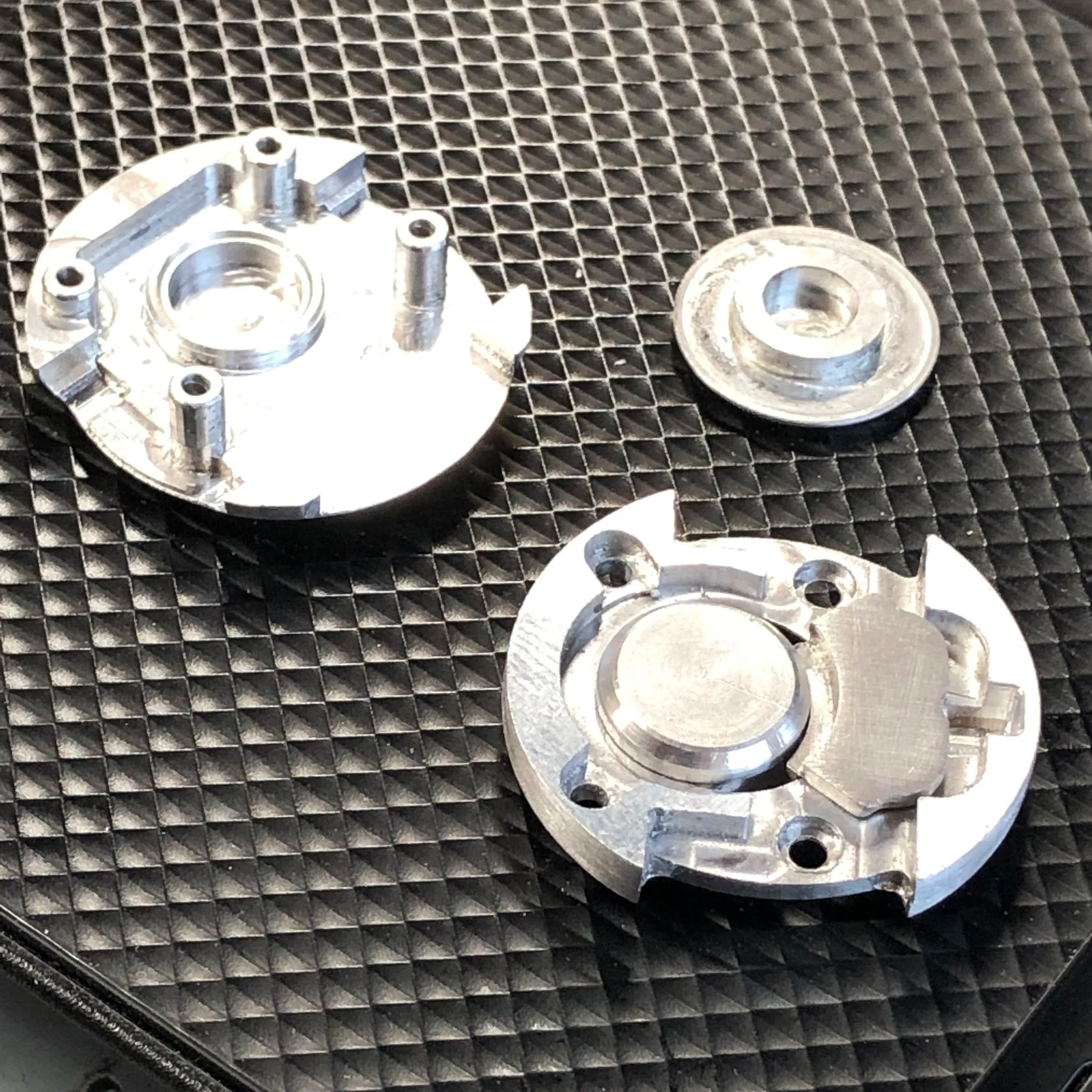

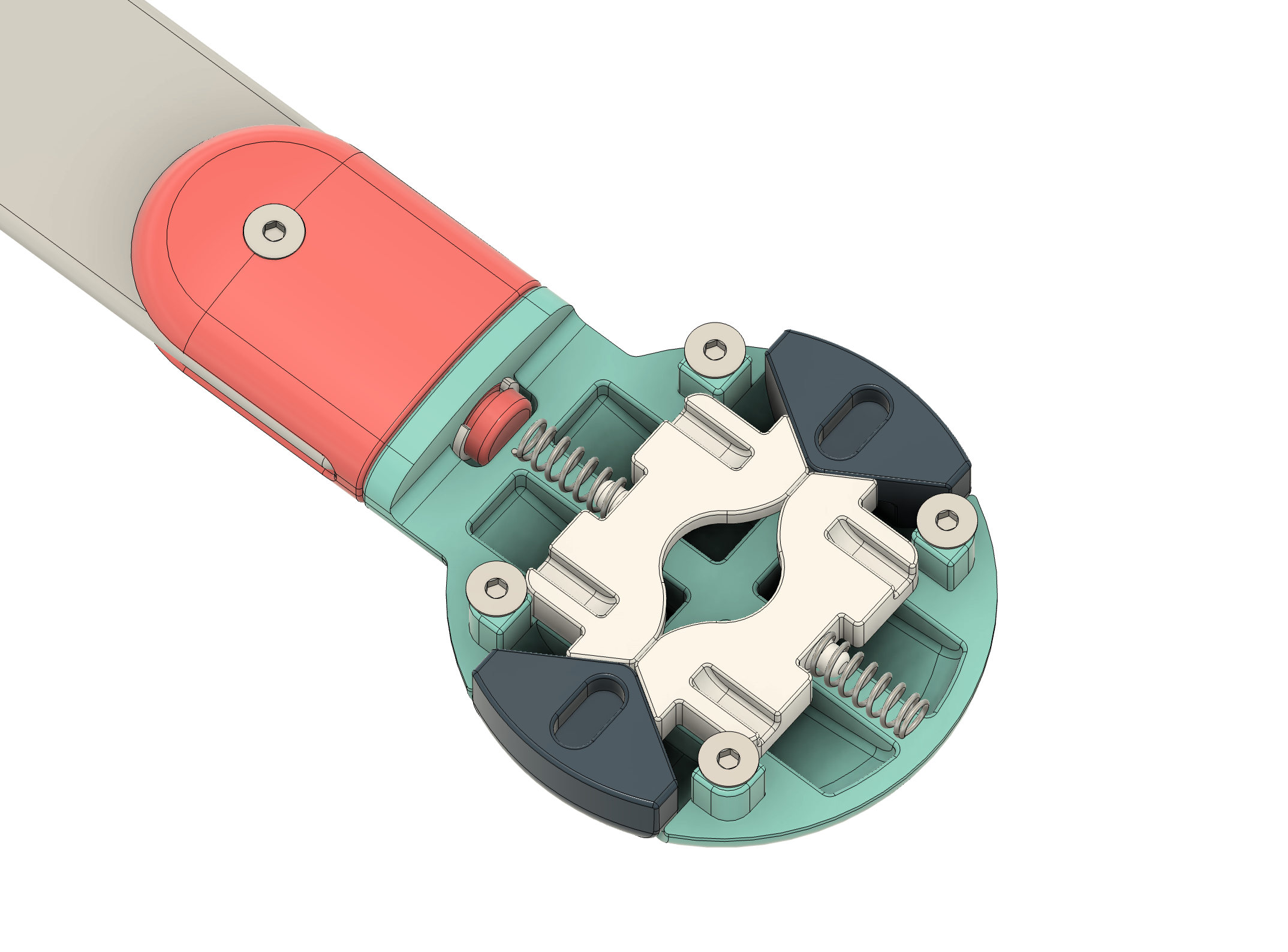

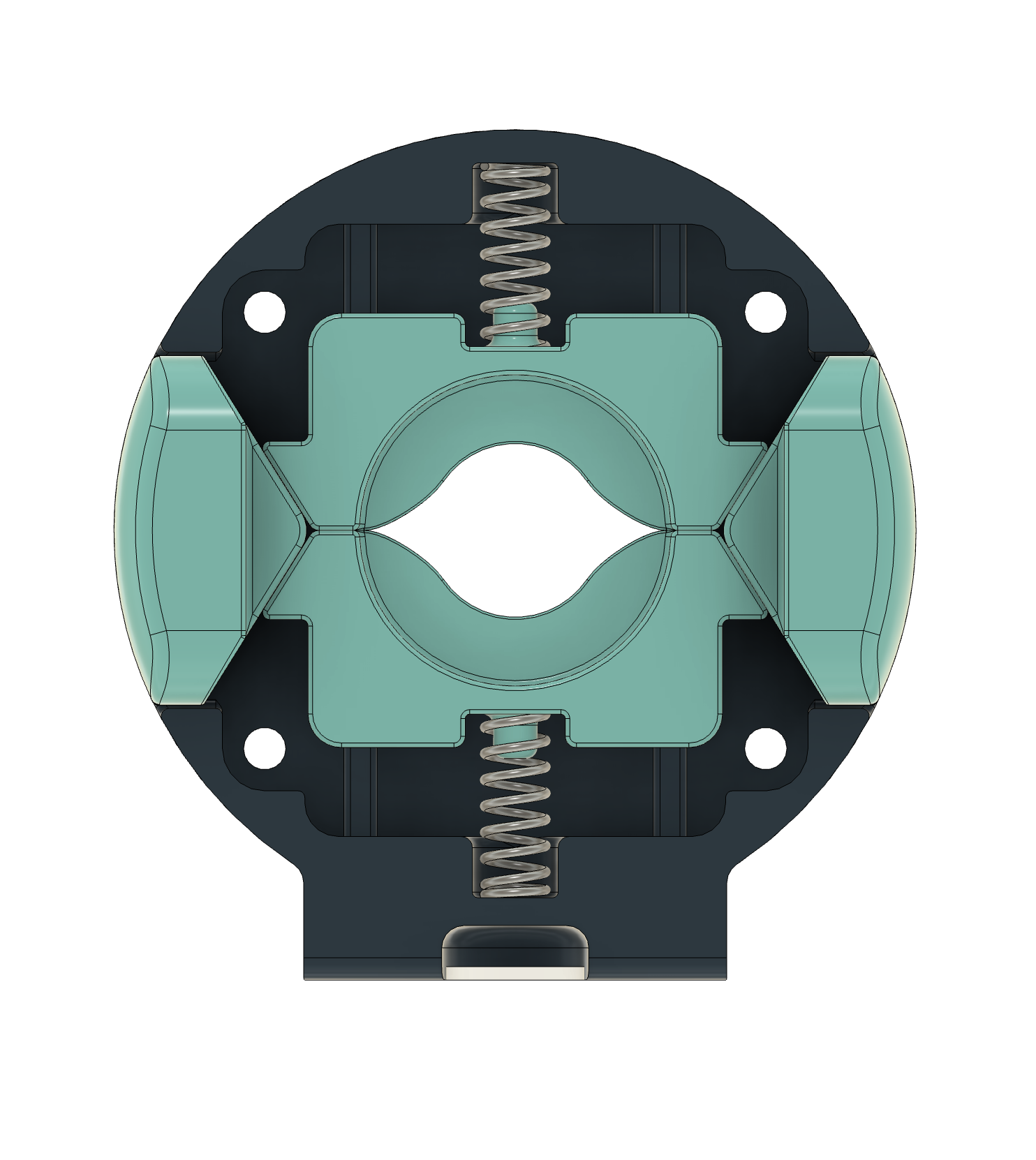

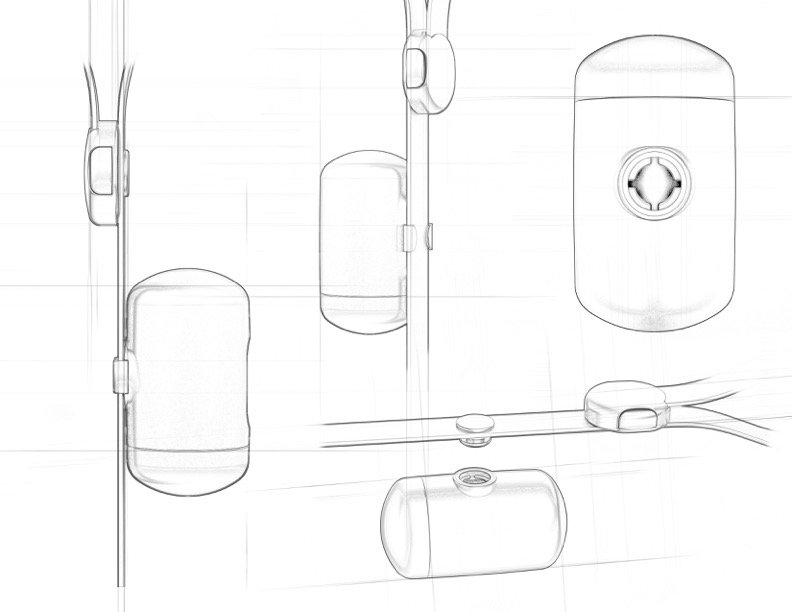

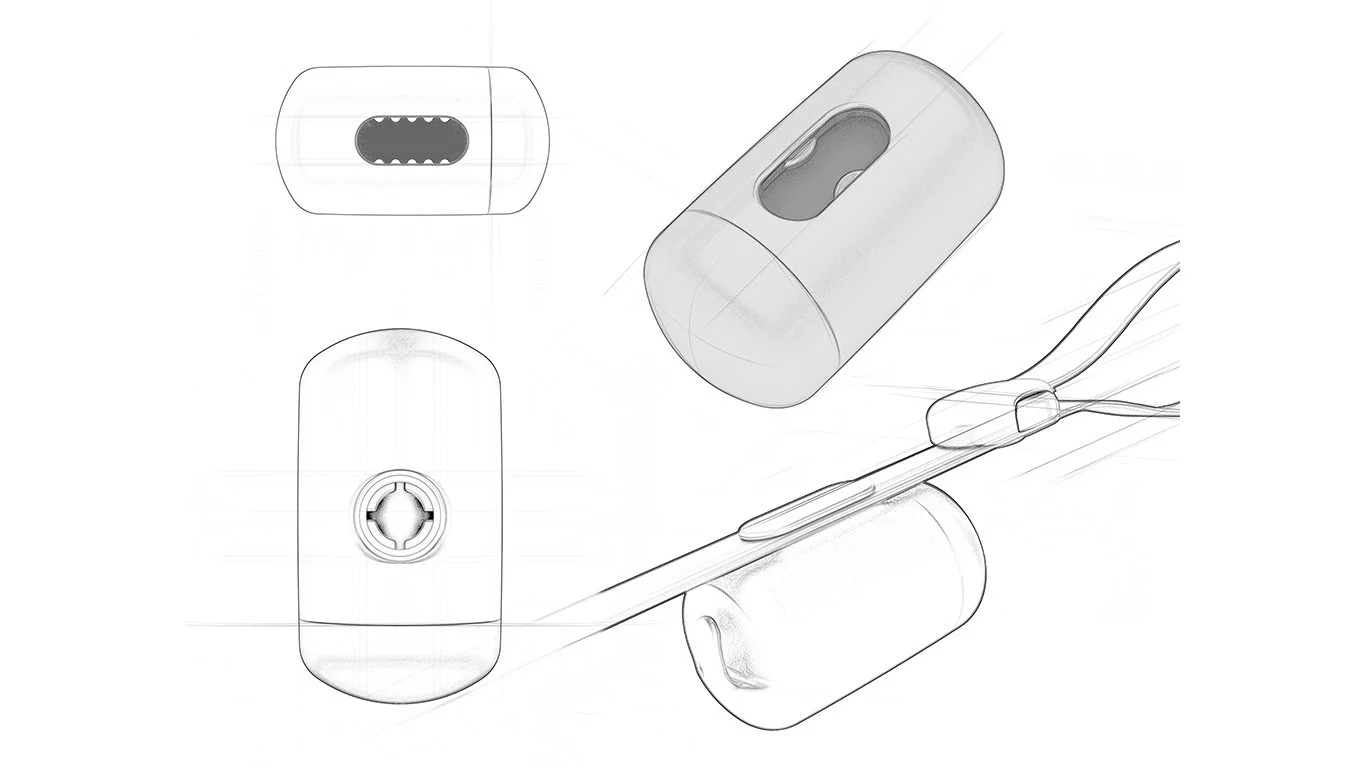

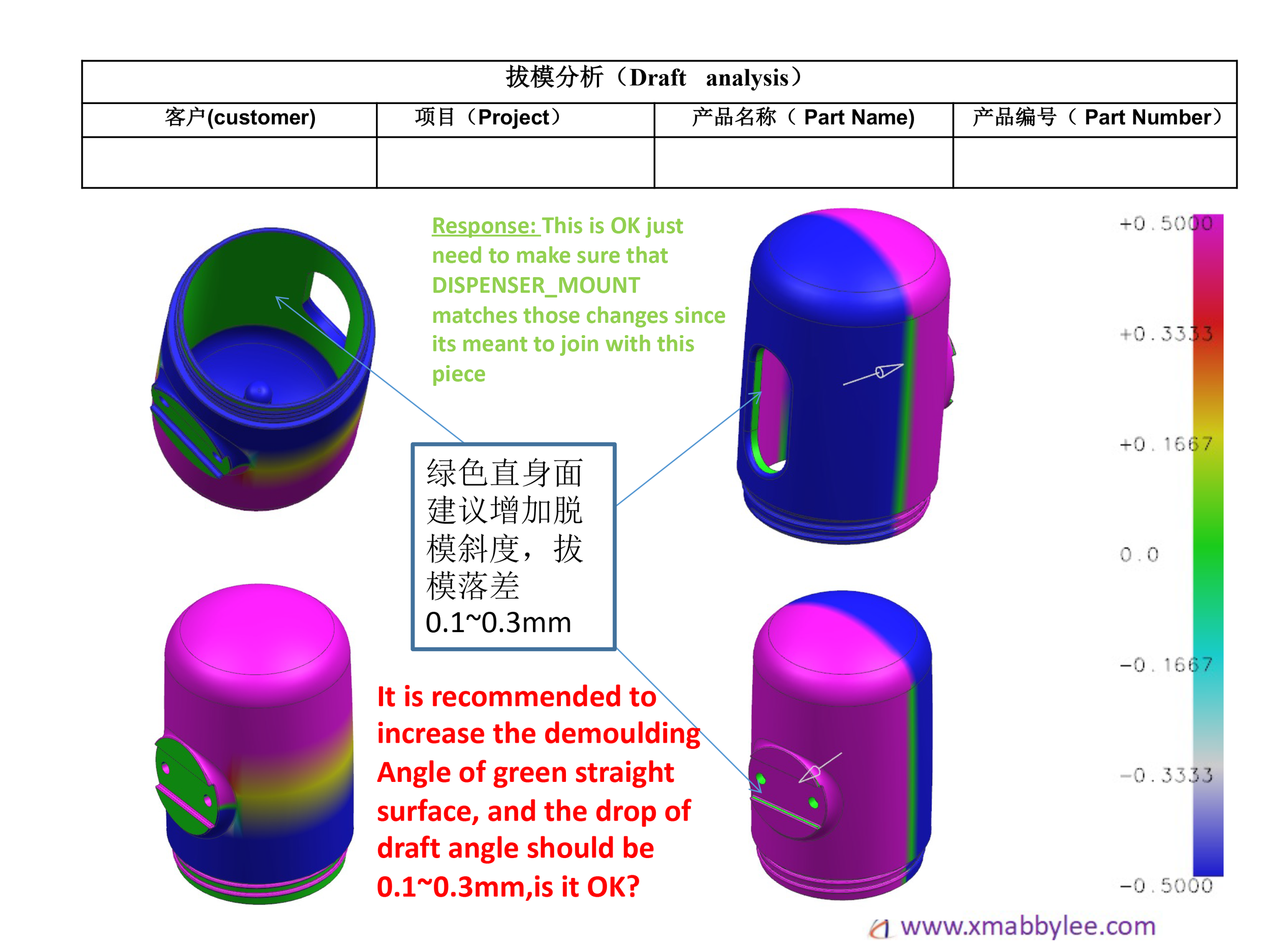

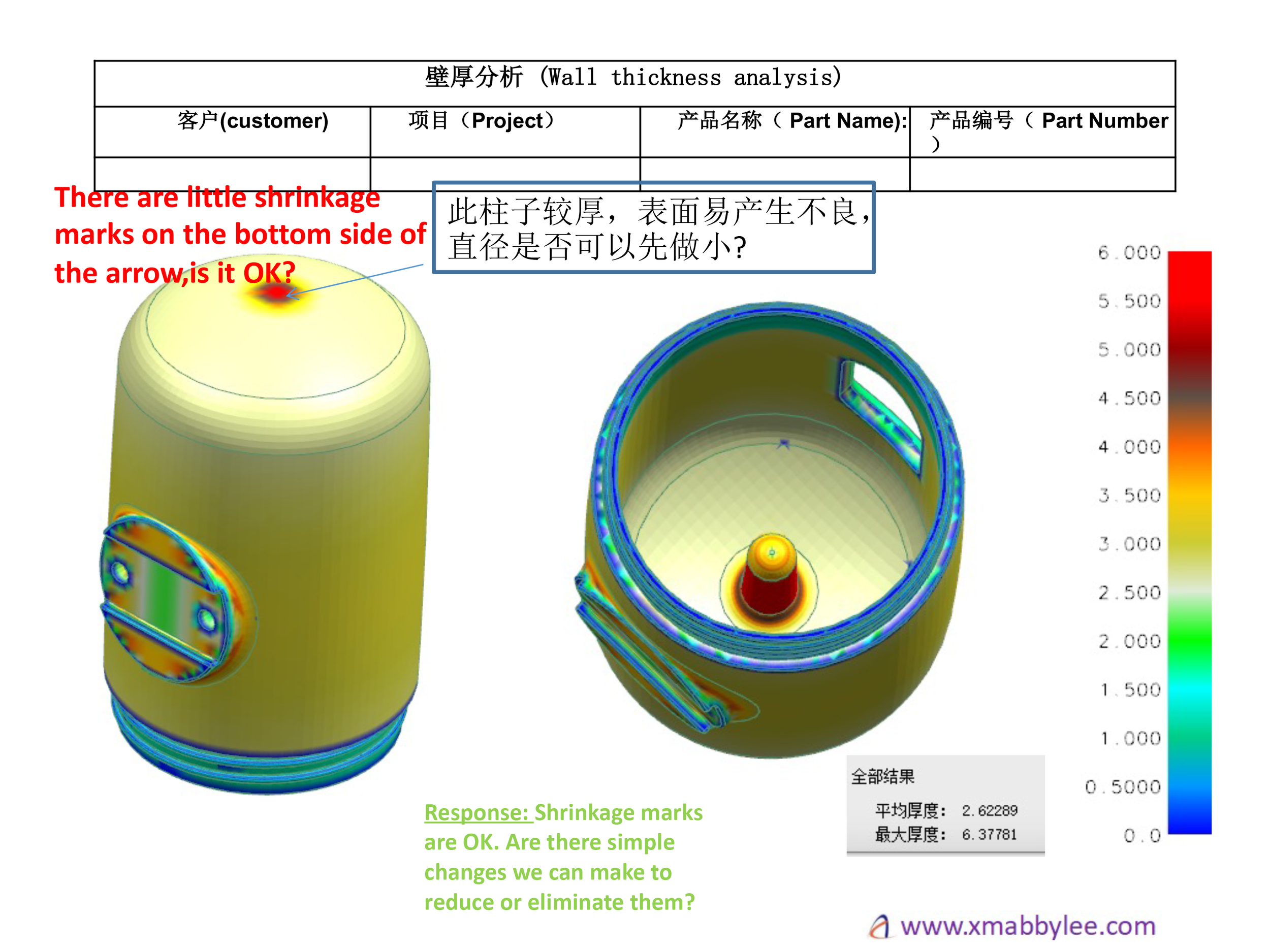

TOMO was built from scratch through a full end-to-end development cycle. I took the product from early sketches → 3D-printed proofs → CNC-machined functional prototypes → real-world testing → rapid iteration → DFM → tooling → mass production. Every stage was hands-on, refining the geometry, mechanics, durability, and usability until the final production-ready system was locked.

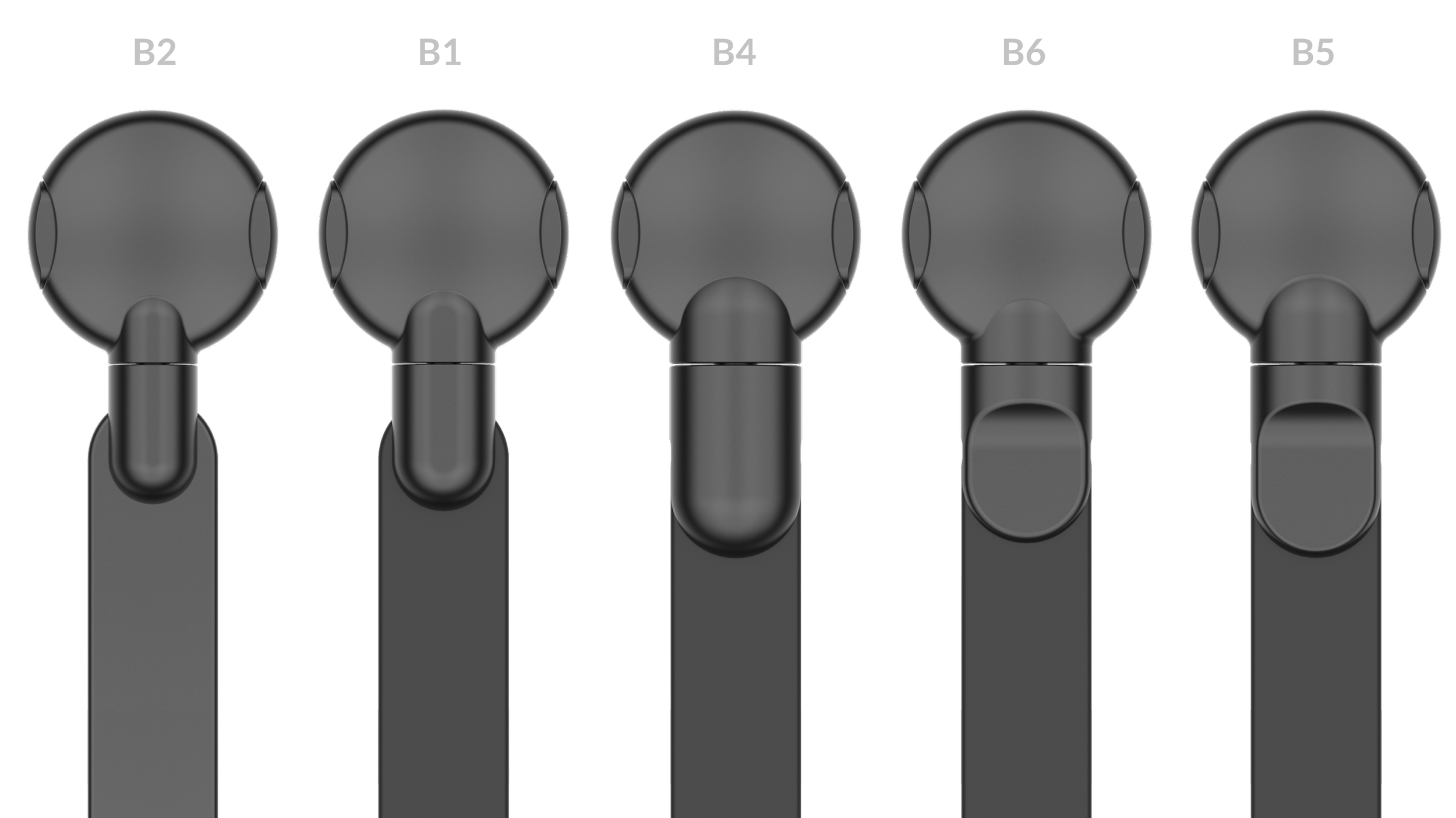

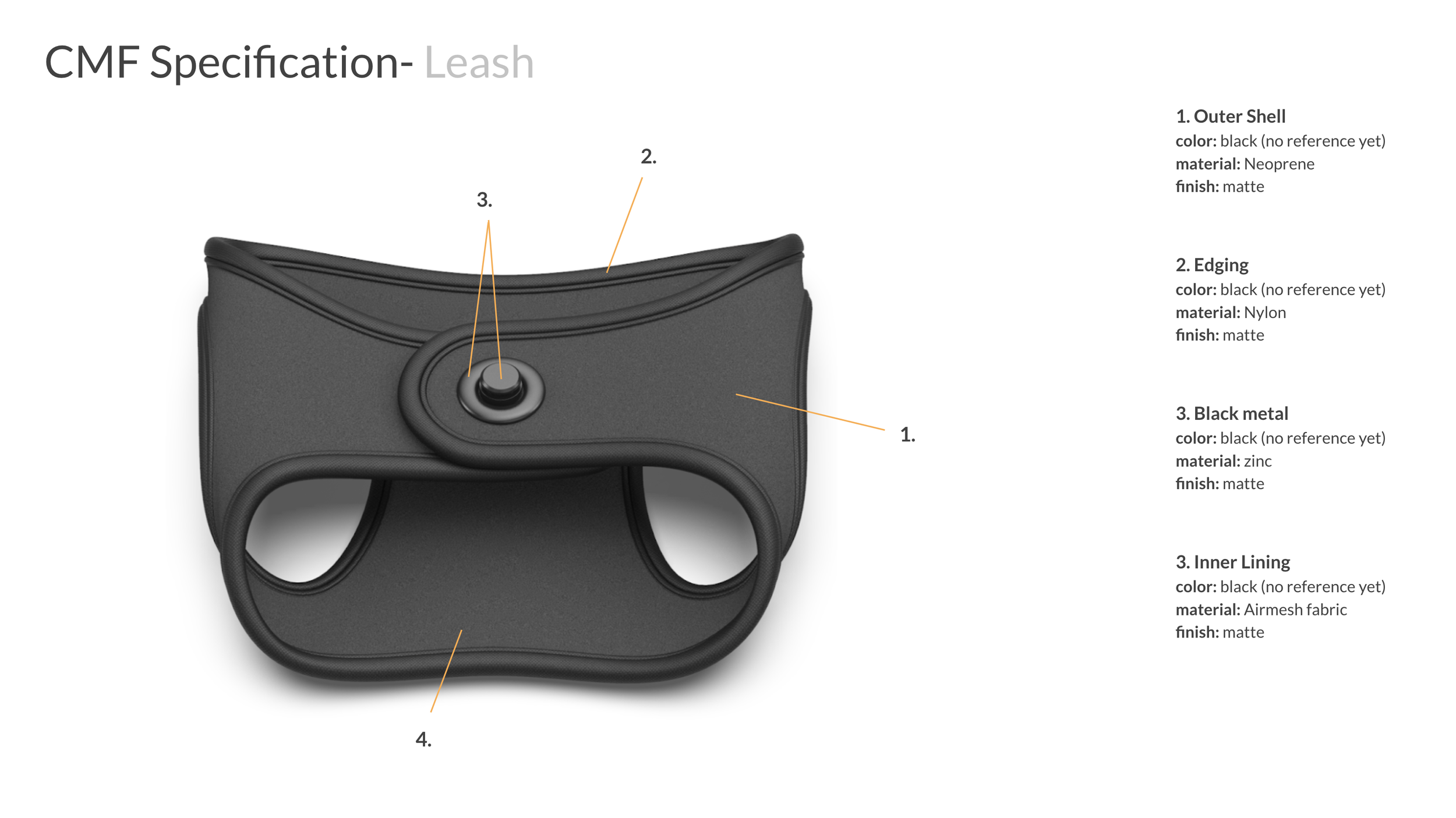

Collar & Latch Design